Custom CAD Integration: Connecting Design and Automation in Engineering Companies

Engineering Design Needs an Upgrade

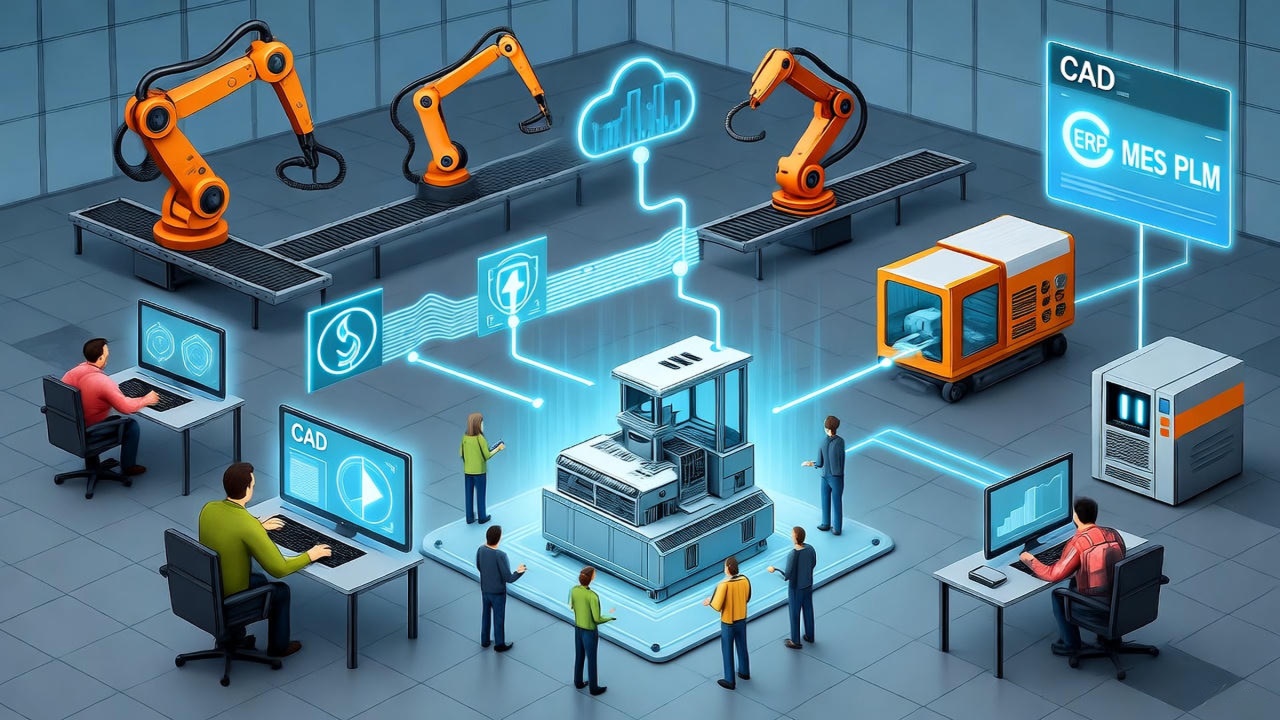

Today’s engineering companies work in high-risk settings where design accuracy, rapid iteration, and manufacturing synchronization are paramount. Even though conventional CAD (Computer-Aided Design) software is vital, it frequently is not flexible and integrated enough to enable complete digital change.Providers offer CAD models and technical documentation for OEM engineers integrating coolers into new systems, supporting CAD integration.

Custom CAD integration is emerging as the strategic switch for engineering companies seeking to close the gap between industrial automation and design systems. Combined with low-code platforms, the custom apps are slashing time-to-market and minimizing manual effort. The GCC computer-aided design (CAD) market is experiencing significant growth due to the increasing adoption of integrated CAD software across various industries.

“Many CAD engineering companies develop software that integrates with CAD systems to streamline the design process.”

- Custom CAD software allows for closer integration between design and manufacturing systems.

- Low-code development cuts deployment time and expense by orders of magnitude.

- Automating CAD processes enhances accuracy, decreases rework, and facilitates real-time collaboration.

- Engineering leaders can lead the way on innovation by making CAD systems digital command centers.

Why Customize CAD Software in the First Place?

Off-the-shelf CAD solutions typically lack the capability to address industry-specific requirements—particularly in industries such as aerospace, automotive, and heavy engineering. Here’s why customization is important:

Typical Shortcomings of Commercial-off-the-Shelf CAD Solutions

- Insufficient integration with PLM, ERP, and MES systems

- Manual data transfer that results in design flaws and time delays

- No domain-specific design rule support

- Inability to repeatable engineering processes

Advantages of Custom CAD Integration

- Synchronized real-time design updates between platforms

- Automation of BOM (Bill of Materials) creation

- Custom UIs and workflows for specialty engineering tasks

- Data interoperability with manufacturing equipment

Is it worth the investment to develop custom CAD for a mid-sized engineering company?

Yes—especially when ROI is quantified in terms of less rework, accelerated project turnaround, and enhanced automation from design to production.

How CAD Integration Drives Industrial Automation

CAD integration is not merely about design—it’s the foundation of intelligent manufacturing. When integrated with downstream systems such as ERP or SCADA, CAD is the single point of truth throughout the product lifecycle.

Key Integration Use Cases

- Automated design-to-production workflows through API-backed low-code apps

- Integrating CAD tools with IoT and sensor data for real-time verification

- Driving robotic assembly or CNC machine code directly from CAD data

- Feeding CAD-generated geometry into simulation platforms or digital twins

Data-Driven Advantage

Custom engineering solutions can enhance CAD with AI/ML functionality—e.g., predictive maintenance notifications based on design tolerances or structural analysis inputs.

Challenges in Custom CAD Development (and How to Overcome Them)

There are challenges, but the payoff is worth it. Here’s how engineering leaders can overcome them:

Common Challenges

| Challenge | Solution |

| Vendor lock-in from proprietary CAD formats | Use open standards (e.g., STEP, IFC) and API-based middleware |

| High development cost/time | Leverage low-code platforms to reduce engineering overhead |

| User resistance to new tools | Ensure UIs are intuitive and mimic familiar CAD interactions |

| Data security and compliance | Build with audit logs, access control, and secure cloud deployment |

How is low-code different from traditional CAD customization?

Low-code facilitates quick prototyping, integration, and iteration through visual workflows—perfect for non-traditional developers—while traditional customization entails full-stack development and longer timelines.

Struggling to incorporate CAD into your digital factory?

Arrange a free consultation with our digital engineering specialists to discuss your use case.

Schedule a Discovery Session

Real-World Example: Custom CAD App in Heavy Equipment Manufacturing

A heavy equipment producer worldwide experienced delays caused by isolated design and manufacturing systems. By connecting their CAD tool with their MES via a custom low-code app:

- Design changes were updated in the production queue in real time

- BOMs were automatically generated and pushed to procurement in real time

- Error rates decreased by 32%

- Engineering cycle time decreased by 4 weeks

Key Stack: AutoCAD + Mendix low-code + Azure DevOps + SAP MES

How to Approach Custom CAD Integration Strategically

1. Audit Your Current Toolchain

- Which systems are currently communicating with your CAD software?

- Are manual handoffs causing bottlenecks?

2. Establish the Integration Scope

- CAD to ERP alone, or to MES too, CRM, PLM?

3. Select the Appropriate Development Method

- Low-code tools such as Mendix, OutSystems, or Microsoft PowerApps for rapidity

- Custom microservices or APIs where necessary

4. Develop for Scalability and Maintenance

- Versioning, rollback support, and modularity

- Embedded analytics to track usage and performance

Can low-code tools deal with complicated CAD data?

Although low-code platforms do not directly process native CAD geometry, they are able to orchestrate APIs, map metadata, and handle CAD-associated workflows effectively.

Frequently Asked Questions

1. Which industries benefit most from custom CAD integration?

Automotive, aerospace, industrial manufacturing, and civil engineering are the sectors that benefit because of intricate design-to-production requirements.

2. How many days does it take to develop a custom CAD app?

With low-code, prototypes are available in 2–4 weeks; complete rollouts will run 3–6 months based on complexity.

3. Is low-code secure for enterprise-class CAD workflows?

Yes, if there is proper governance, authentication, and cloud compliance, low-code applications can be compliant with enterprise security requirements.

4. What’s the cost range of CAD integration projects?

Custom CAD applications through low-code can begin at $25,000–$50,000 compared to conventional dev processes that would cost 2–3 times as much.

Ready to connect your design and production systems with a tailored CAD solution?

Let’s create your next-gen engineering stack together.

Book a Custom CAD Discovery Session